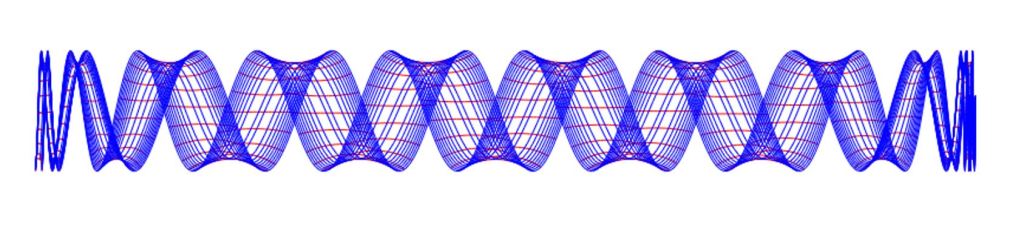

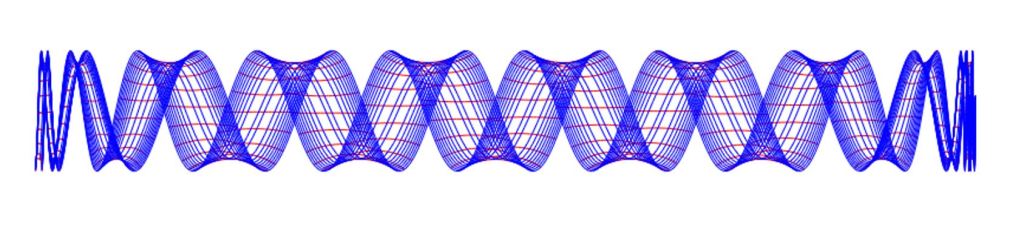

CylindriCurves

Precision Conveying Systems for Lid Sterilization & Treatment

This project based in France delivers automatically generated 3D models of advanced conveying systems designed to sterilize or treat can ends (or lids) using a range of technologies, including:

- UVC mercury lamps

- Pulsed light (flash lamps)

- Chemical spray nozzles

- Vision inspection systems

- Air rinsing units

How It Works

The system handles lid stacks with precision:

- Separates individual lids from the stack

- Rotates each lid 90° for full exposure to the selected treatment

- Processes both lid surfaces through UV, flash, or chemical application

- Rotates lids back to their original orientation

- Restacks the treated lids

Smart Automation

The entire device is automatically configured based on user-defined parameters. An intelligent algorithm generates tailored 3D CAD models to match your specific sterilization method, lid size, and throughput requirements.

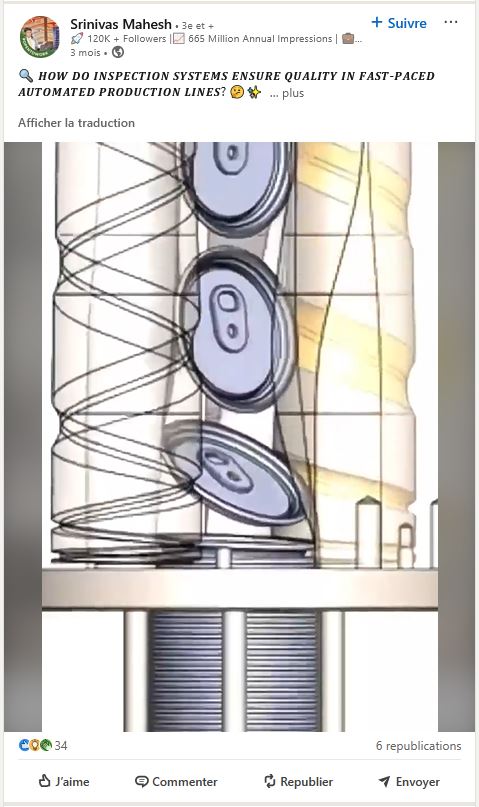

Flexible Integration

As demonstrated in the video, violet cylinders represent UVC mercury lamps, but the system can easily be adapted to alternative components:

- Swap UVC lamps for flash lamps for pulsed-light treatment

- Integrate vision cameras for quality inspection

- Add chemical nozzles or air rinsers depending on hygiene needs

This modular design makes the system highly adaptable to various production environments and compliance standards.

Easy Integration on Seamer Infeed Systems

This system is designed for easy installation at the lid infeed channel of a seamer, offering a plug-and-play solution with minimal disruption to existing lines.

Key Advantages

- Continuous, Smooth Guiding

The guiding surfaces are engineered for zero transitions—ensuring smooth, uninterrupted movement throughout the process. - Optimized Motion Control

The core algorithm precisely manages speed, acceleration, and jerk, resulting in gentle yet controlled lid handling. - High Repeatability & Robustness

Advanced motion planning makes the system consistently reliable, even under varying throughput conditions.

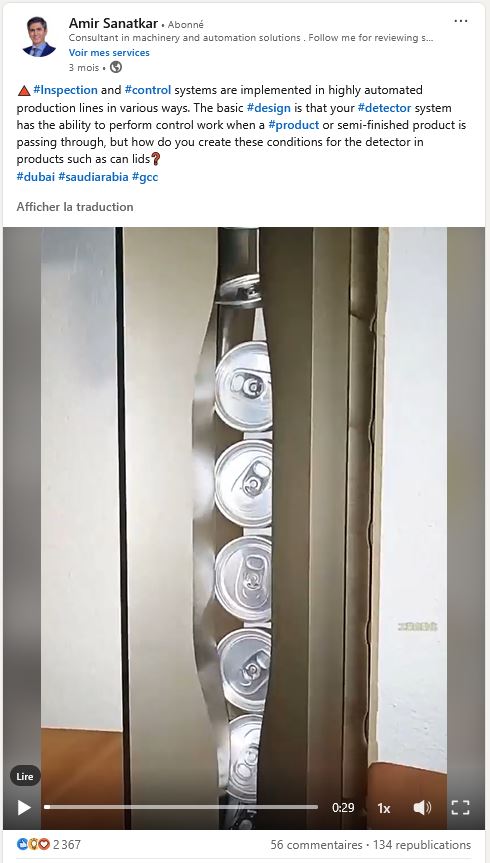

Proven Concept

Below are videos of our 2 prototypes, demonstrating the concept in action. The central treatment zone provides exceptional exposure to nearly the entire lid surface, allowing for:

- Efficient sterilization

- Accurate vision inspection

- Consistent surface treatment

These prototypes confirm the feasibility of the solution and the ability of the algorithm to generate correct surfaces with different parameters.

The video with Proto V2 shows a 8 minute long run without problem.

Industry Attention & Global Engagement

Several prototype videos have attracted significant attention on LinkedIn, where they were reshared and remixed by industry influencers—generating worldwide discussion, including valuable feedback from major canning line manufacturers.

This unexpected visibility highlights strong market interest and reinforces the relevance and potential of the solution within the global packaging and food processing industry.

Business opportunities

If you are a machine manufacturer in the food/beverage industry and are interested by this topic, 3D files can be purchased. We can sell the files used to make the Proto V2. We can also generate new files depending on your parameters (lid size, treatment length, speed…).

Get in Touch

For inquiries, collaboration opportunities, or technical discussions, please contact us at:

📧 cylindricurves@gmail.com

We look forward to connecting with you.